Mesin Pengolah Makanan Ikan

1.Extruder Motor utama: Siemens Cina 2.Relay: ABB 3.converter: Delta, Pioneer, CHNT, Schneider atau menyesuaikan. 4.Dyer: sistem sirkulasi udara panas menghemat biaya & listrik. 5. bahan Mesin: stainless steel. 6.Guarantee Waktu: 2 tahun 7. Kami menyediakan formula dasar ketika Anda memesan mesin kami dan mengirim insinyur kami untuk uji coba instalasi dan melatih pekerja Anda 8. Sertifikat: CE, TUV, BV.

Mesin Pengolah Makanan Ikan

Deskripsi Produk Mesin Pengolah Makanan Ikan

Mesin Pembuatan Makanan Ikan kami dirancang untuk memproses berbagai macam resep.

Fish Food Making Machine dapat menghasilkan sejumlah tekstur, bentuk, ukuran, rasa dan warna.

Tujuan kami adalah menyediakan alat produksi yang fleksibel dan skalabel untuk memproduksi Mesin Pengolah Makanan Cat berkualitas tinggi, lezat, dan bergizi.

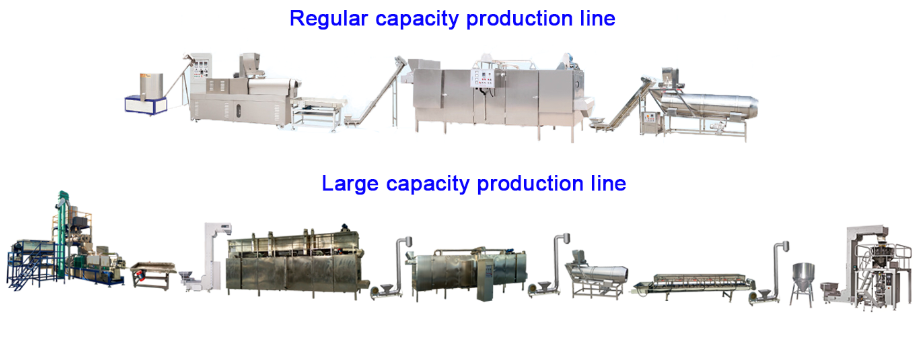

1. Rincian lini produksiMesin Pengolah Makanan Ikan

Kapasitas | 120kg-4000kg |

Sumber Daya listrik | Berdasarkan fase 380V 50 Hz 3. Disesuaikan sesuai dengan kekuatan lokal Anda. |

Detail mesin | 1.Stainless steel,: 201, 304, 316, berdasarkan permintaan 2. Bagian listrik bisa ABB, Delta, Fuji, Omron, Siemens; Merek terkenal sebagai permintaan Anda. |

Sertifikat | CE, GOST, TUV, BV |

Bahan baku | Makan jagung, tepung, bungkil kedelai, bungkil kacang. Tulang / daging / ikan / bubuk udang, dll. |

Tipe produk | makanan anjing, makanan kucing, pakan ternak; pakan ikan mengambang & pakan ikan tenggelam |

Bentuk produk | Makanan hewan peliharaan: Pelet Pakan ikan: Granule, Pellet, stick, tablet |

Ukuran produk | Diameter Minimum: 1.5mm |

2. Keuntungan Mesin Pengolah Makanan Ikan

1. Kami mengkhususkan diri dalam ekstruder kapasitas tinggi yang bisa mencapai 4000kg / jam

2. Bahan sekrup: Baja paduan (38CrMoAL) dengan proses nitridasi. Kekuatan tinggi dan tahan aus.

a) Dengan kemampuan membersihkan diri yang baik, tidak perlu melepas laras dan sekrup untuk dibersihkan.

3. SIMENS (Cina) Motor

4. Ini mengadopsi konverter kecepatan-disesuaikan pada sistem makan, sistem ekstrusi dan sistem pemotongan.

a) Food grade stainless steel perangkat makan sekrup kembar menjamin bahan stabil makan dalam seluruh proses makanan.

5. Adopted the Delta inverters, ensure the extruder better running.

6. The gearbox has automatic lubrication function, which prolong service life of gears.

7. Cutting knife is fixed in the die head seat, rotary cutting driven by V-belt.

3. Technical Parameters of Fish Food Making Machine

Model | Installed power | Real power | Capacity | Dimension |

ZH65 | 35 KW | 22kw | 120-150kg/h | 39000x1200x2200mm |

ZH70 | 50kw | 37kw | 200-250kg/h | 41000x1500x2200mm |

ZH85 | 110kw | 75kw | 300-500kg/h | 43000x3500x4300mm |

ZH95 | 151kw | 110kw | 1-1.2 ton/h | 4700x1900x4800mm |

ZH135 | 425kw | 335kw | 3-4 ton/h | 5200*2000*4200mm |

4.Production process of Fish Food Making Machine

Flour raw material mixing-extruding and shaping-drying-flavoring-cooling-packing

Packaging & Shipping of Fish Food Making Machine

Packing:Floating Fish Feed Plant are always wrapped by film completely and safely and then packed in strong fumigation-free case or 20'/40' container for delivery.

We take good care of each machine for you

Delivery: 20-30 days after receiving advance payment.

Our Services

Company Information

Jinan ZhuoHeng Machinery Co., Ltd is an industry and trade integrated enterprise. The company is committed to R & D extrusion machinery and related ancillary equipments. It is covering mainly machinery and equipment for corn meal milling system, corn flakes/breakfast cereal system, baby food system, corn puff snacks system, pellets system, artificial rice system,soy protein system; as well as pet food/fish food system.

Our Services

Pre-sale service | Communicating with customers and learn your requirement |

Providing professional advisory services | |

Providing solutions according to customers’ requirement, And offer the quotation | |

Providing on-site visit to our factory | |

Providing samples | |

Selling service | Confirm every terms and details and sign contract with customers |

Manufacturing machines according to contract. | |

Trial running after production. | |

Packing machines and delivery on time | |

Providing relevant documents for Custom clearance (If necessary) | |

After-sale service | Send engineers for installation, trial running and training workers. |

Handling the problems occurred during use. | |

Supply spare and wearing parts on discount. | |

Help customers to solve any other problems |

Certificates

FAQ

1. Are you a manufacturer or a trading company?

We are a professional manufacturer of food & feed extrusion machine

2. What's the price of your machines?

You can inquiry to us directly

3. What is your payment terms?

Recommend to use Alibaba’s Trade Assurance.

T/T or L/C; by T/T 30% as down payment, 70% by T/T before delivery, L/C before shipment.

4. Can we provide the formula to you?

We can provide basic formula for producing the food etc.

And help customer to produce good quality food according customer’s detailed formula.

5. What is the workshop size required?

The production line can be put in straight line and also can change the direction according to your factory size.

We can design the layout according to your factory size.