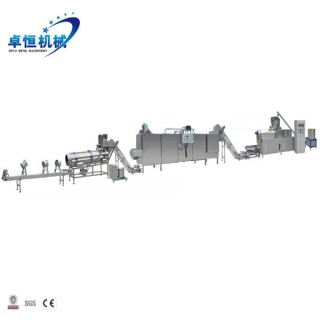

Corn Flakes Production Line Machinery

1. Zhuoheng twin-screw extrusion line efficiently produce a vast range of cereal flakes that meet an evolving demand for consumption at breakfast or snack.

Twin screw extrusion lines are simpler and more cost effective compared with batch cooking systems traditionally used for flakes manufacturing.

2.Many raw materials are eligible with coating recipes such as sweet syrups, honey, chocolate and other compositions.

3. Flakes and loops are either consumed plain or coated with a variety of sugars, malted ingredients, honey, fruit flavors, chocolate, etc. .

To meet the increasing demand for healthy cereals, whole grain or grains enriched with fibers, vitamins, minerals and other nutrients are also used.

Corn Flakes Production Line Machinery

Production description

Breakfast Cereal Food is a kind of crispy food which is processed by twin- screw extruder and takes grist as basic material. The majority are fiber flimsy, and either too sugary or too salty. Snacks food processing line can be directly extruded from the extruder, dryer and seasoner, we can produce all kinds of snacks and different shapes by adjusting the dies from extruder.

Variety shapes are available for ball, tube, stick, ring, fruit loop, star, wheel and flower and heart, shape by adjusting the mould in the extruder.

Raw Material : Corn Grits (Powder), wheat flour, rice flour, oat meal, other grain meals.

Processing Flow Chart

Model | Installed power | Actual power | Output | Dimension |

ZH65 | 35kw | 22kw | 150kg/h | 3*0.8*1.95m |

ZH70 | 50kw | 33kw | 250kg/h | 3*1.1*2.25m |

ZH85 | 97kw | 63kw | 500kg/h | 3.58*1.04*2.05m |

Poroduct samples

Our service

After-Sales Service

* Inquiry and consulting support

* Sample testing support.

* View our Factory.

Pre-Sales Service

* Training how to install the machine.

* Engineers available to service machinery overseas

Packing and delivery

| Item | Material & Brand |

Screws material | 38CrMoAl Alloy steel by Nitriding process. High strength and wear-resistance | |

Body material | Food grade stainless steel | |

Main motor | Siemens (China) | |

Inverter | Pioneer or Delta, ABB, etc. | |

Electric parts | CHNT or ABB, Schneider, etc. |

Capacity | 120kg/h - 500kg/h |

Power Supply | Based on 380V 50 Hz 3 phase. |

Certificate | CE,SGS,BV |

Product shape | rings, flowers, balls, strips, moons etc. The shape is customizable. |

Our customers

Turkey Uzbekistan

Zimbabwe Mexico

Certifications

FAQ

Q1. Are you a manufacturer or a trading company?

A: We are a professional manufacturer of food & feed extrusion machine.

We have own factory and R&D department. SGS has certified our company on site.

Q2. What is your payment terms?

A: Strongly recommend to use Alibaba’s Trade Assurance.

T/T :30% prepayment,70% before delivery. L/C at sight is available.

Other payment is negotiable.

Q3. Do you offer guarantee for the products?

A: Yes, we offer 1-2 years warranty to our products.

Q4. What about the lead time?

A: Regular products:20-30 working days

Customizable products:30-40 working days

Q5. Can you provide food or feed formula ?

A: We can provide basic formula for produce the food etc.

And help customer to produce new products according to customer’s formula.

Q6. What after-services do you provide?

A: Send engineers for installation, trial running and training workers at customer's site.

Handling the problems occurred during use. Supply spare and wearing parts on discount.

Help customers to solve any other problems

Welcome to visit our factory